Prehistoric Problems, Modern Solutions

Safe-T-Rack Technicians Conquer All Manner of Challenges,

with one goal in mind: protect teams from arc flash risk (and raptors).

The Need for Safe-T-Rack: Assessing the Location

Amid the mountains and mists of a remote island, beyond a battalion of caution signs and a literal boatload of electrified fencing, a large power plant for a client (who has requested to remain anonymous) battled an energy concern: how to reliably and safely maintain their facility, especially when their remote racking application proved cumbersome. Due to the unique nature of the facility, switchgear was located in several locations across the island, all requiring regular maintenance to ensure consistent distribution of uninterrupted energy – used to contain the island’s undisclosed and dangerous wildlife.

For years, this power plant used a functional but inconvenient method to maintain and operate their breakers. The employees at the facility were required to disassemble and relocate the remote racking system whenever it was used. At times, heavy machinery was even required – cranes and other equipment added additional complications. The crew routinely disassembled and transported the remote racking system across the island to the next breaker location, where they would reassemble the pieces at the next cubicle. This remote racking process was time-consuming and labor-intensive, requiring multiple employees and a staggering amount of time and resources, not to mention additional exposure to island hazards.

However, after one too many close calls involving operators and some of the island’s toothier inhabitants, the facility was forced to reconsider their approach to remote racking. Their existing equipment was unwieldy, awkward, and inefficient – and was now putting their employees at risk. The answer was simple: find a remote racking application that champions portability, versatility, and operator safety so that the facility could successfully maintain and operate their equipment without downtime or arc flash risk.

Safe-T-Rack Devises a (Remote) Solution for Island Operators

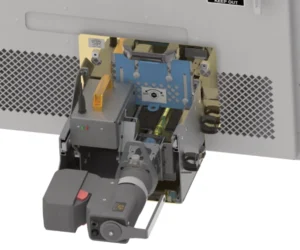

In alignment with this goal, the facility reached out to Remote Solutions LLC and was immediately connected with a team of experienced engineers, designers, and technicians. Within days, the Remote Solutions team presented several existing applications – each designed specifically for many of the commonly manufactured cubicles and breakers on the island. For some of the more nuanced cubicles, nestled into the hillsides or camouflaged from the island’s rowdier wildlife, Remote Solutions offered to create custom applications. The team of designers and engineers at Remote Solutions is adept at creating new and effective remote racking applications to meet the setup and equipment restrictions of any client – and this island’s facility was no exception.

Safety is at the forefront of design and engineering practices at Remote Solutions, and all applications, software, and products are created with the goal of protecting equipment operators from arc flash risk. Additionally, the Safe-T-Rack system is programmed to operate with properly installed and maintained equipment, which protects operators – a nuance that also allows Safe-T-Rack to uncover equipment issues that may have gone unnoticed. Thanks to these software parameters and safeguards, Safe-T-Rack protects both facilities and operators from potentially dangerous situations (at least as far as electrical equipment is concerned).

Safe-T-Rack Boldly Installs Remote Racking Equipment

Within weeks of first contact, Remote Solutions sent a team of brave installers to the island, deftly wielding their remote racking applications and immediately installing the Safe-T-Rack system on several applicable breakers. The installers were able to implement the remote racking applications even under duress, persuading even the most avid naysayers to move quickly and effectively toward a safe solution (feeling the predatory breath of, um, ‘arc flash risk’ at their necks helped to speed the process). This expedient transition allowed the facility’s team to immediately begin saving time, energy, and effort – implementing the new remote racking system almost instantaneously and increasing efficiency at the facility.

From that fated day, the facility no longer feared for the safety of their employees – where remote racking was concerned. (It should be noted here that one of these installers sustained an injury from the island wildlife in an unrelated circumstance that obviously wouldn’t violate the facility’s nondisclosure agreement and did not involve a dinosaur in any way). The installer made a full recovery – but not everyone is so lucky. If it had been an arc flash incident without Safe-T-Rack installed, this story would read differently.

All Joking Aside: About Safe-T-Rack

Remote Solutions designs custom remote racking applications for all manner of breakers, contactors, and switchgear. As was the case with this facility, often there is a pre-existing design for a specific breaker or manufacturer; in these situations, the sales team can connect you with an application that suits your needs and timeline with a swift turnaround. Learn more about Safe-T-Rack Remote Racking applications at our website or contact our sales team to learn which application is right for you today.

For more information about Safe-T-Rack remote racking systems, contact our team today!

Find a Remote Racking Solution for your Equipment! Search breaker, manufacturer, or amperage here!

The Latest News from Remote Solutions:

Switchgear Manufacturer turns to Safe-T-Rack for Custom Remote Racking Solution

Switchgear Manufacturers Seek Effective, Reliable, and Portable Remote Racking Options for Equipment Builds Safe-T-Rack systems are custom-built for specific lineups, offering manufacturers a safe, effective, customer-enticing remote racking option for new switchgear builds. As with All Things, It Starts with Building Something: Since the early days of the electrical grid, there have been lineups and

Power Generation Facility Implements Safe-T-Rack After OSHA Reportable Arc Flash Incident

The Time to Implement Safe-T-Rack is NOW Before an Arc Flash Incident Occurs An OSHA Reportable Lost Time Incident Occurs In 2020, on the East Coast of the United States, a power generation facility experienced an unfortunate arc flash event which severely injured an operator and significantly damaged equipment. A General Electric Limitamp contactor arced

Safe-T-Rack Adapts Remote Racking System to Operate Overhead Switches with new Product: ULTRAVIOLET

ULTRAVIOLET: Remote Overhead Switch Operation using the Safe-T-Rack Remote Racking System The Customer Request: Remote Overhead Switch Operation For almost 20 years, Remote Solutions LLC has developed and refined innovative, portable remote racking systems with the goal of making arc flash safety convenient and effective for facilities all over the world. Safe-T-Rack remote racking systems