The Safe-T-Rack©

Remote Racking System

The industry's most portable, effective, and capable remote racking system, racking over 300 breakers and expanding our product line every day.

Engineered for safety and success to operate circuit breakers, contactors, valve controls, ring main units, and more - all custom designed by our team of engineers and designers!

This Remote Racking system consists of:

a Motor Drive Unit,

a Smart Drive Bracket,

and a state-of-the-art Handheld Controller

powered by 18V and 28V Milwaukee batteries.

Learn more about these parts and understand the industry-leading remote racking system below!

Because Distance is the best Arc Flash Protection™

A Quick Overview of our Remote Racking System

Understanding the Safe-T-Rack ©

Remote Racking System:

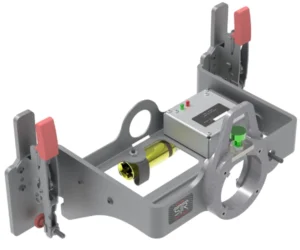

The Safe-T-Rack © Smart Drive Bracket is application-specific, designed to suspend from or secure to the cubicle of a breaker and support the Motor Drive Unit (MDU) in order to complete the remote racking process. An SDB is designed specifically by application, but usually includes:

- Drive Rings with Locking pin – to support MDU during racking process

- Smart Card with pre-installed software specific to the breake

- Communications Cable – will attach to MDU during racking process

- Keyhole Slots or Mounting Hardware to secure SDB to breaker in some applications

- No-mod designs available for some applications.

There are multiple styles of Smart Drive Brackets, each named with its own color code and specifically designed for each breaker or cubicle setup by our talented team of designers and engineers. Some SDBs are suspended from a cubicle using a pre-installed Cubicle Kit, which usually consists of shoulder bolts mounted to the cubicle. assuring efficient, accurate, and secure placement of the MDU and alignment with racking port during every racking sequence.

There are multiple styles of Smart Drive Brackets, each named with its own color code and specifically designed for each breaker or cubicle setup by our talented team of designers and engineers. Some SDBs are suspended from a cubicle using a pre-installed Cubicle Kit, which usually consists of shoulder bolts mounted to the cubicle. assuring efficient, accurate, and secure placement of the MDU and alignment with racking port during every racking sequence.

Smart Drive Brackets can also be “No-Mod” in certain cases, using a variety of technology, including magnets or locking clamps to secure to a breaker and requiring no permanent alterations to customer equipment. Talk to our sales team today to learn if one of these designs is available for your equipment; our team will design a custom bracket for your needs, if one of our existing applications does not fit your needs!

Many Smart Drive Brackets ( SDBs) are suspended from the cubicle using a pre-installed Cubicle Kit, which usually consists of shoulder bolts mounted to cubicle. assuring accurate and secure placement of the MDU during every racking sequence. Both Cubicle Kit and Smart Drive Bracket (SDB) are labeled with correct color code for that application.

Cubicle Kits are installed with a custom installation template, which assures correct placement of shoulder nuts and prevents incorrect hardware mounting on cubicle. Our field support team can perform this installation process, or instructions are available for customers to install cubicle kits on-site at their own facility.

Smart Drive Brackets can also be “No-Mod” in certain cases, using magnets or locking clamps to secure to a breaker and requiring no permanent alterations to equipment. Talk to our sales team today to learn if one of these designs is available for your equipment!

The patented Safe-T-Rack Motor Drive Unit (MDU) is powered by rechargeable Milwaukee batteries, a brushless motor, and tightly integrated gear reduction system.

The patented Safe-T-Rack Motor Drive Unit (MDU) is powered by rechargeable Milwaukee batteries, a brushless motor, and tightly integrated gear reduction system.

Weighing in at only 9 pounds, the MDU is lightweight enough to be portable and convenient but capable enough to remotely rack heavy load and vertical lift breakers. Force feedback technology and custom software allows specific turncounts and speed profiles for each application and mimics human performance and prevent damage to equipment.

The MDU works in tandem with the Smart Drive Bracket (SDB) and Handheld Controller (HHC) to remotely rack a breaker. The MDU is mounted onto the Smart Drive Bracket (SDB) and, once secured in place, interacts with the racking port, following directives from the user operating the Handheld Controller (HHC).

The Safe-T-Rack© Handheld Controller is custom-built in our Tucson, Arizona facility and is pre-loaded with software and capability to interact with applicable breakers and systems, assuring a safe and effective racking process.

The Safe-T-Rack© Handheld Controller is custom-built in our Tucson, Arizona facility and is pre-loaded with software and capability to interact with applicable breakers and systems, assuring a safe and effective racking process.

The Handheld Controller allows the user to interact with the SDB via a 50′ Communication Cable, and displays important information, including desired result of racking process, current known status of the breaker, progress and updates during racking sequence, and error or recovery information, if applicable.

This patented design was created with portability, ease-of-use, and functionality in mind.

Every application is custom-designed to fit your breaker and cubicle. If we don’t have an existing application for your equipment, we’ll design one!

Some common accessories in a Remote Racking System include:

- Tool Adapter Assembly – attaches to MDU to reach/interact with racking shaft

- Communication Cords – used between MDU and SDB and SDB and HHC

- Spanner Bar Assembly – extends across cubicle face to support SDB

- Interlock Manipulator- for equipment that also requires operation of interlock for successful operation.

- Batteries and Charger – each kit includes two (2) Milwaukee brand batteries and a battery charger. We use the best available batteries, with replacements available from a variety of locations globally.

- Intermediate Tool Assembly – integrates with interlock/racking port to successfully rack breaker

Not sure what tools or accessories your equipment needs? Contact our sales team today!

The Safe-T-Rack Portable Kit includes a Motor Drive Unit (MDU), Handheld Controller (HHC), Batteries and Charger, and Communications Cable. Available in both M28 and M18 varieties, these kits can be utilized on all corresponding Safe-T-Rack Smart Drive Brackets.*

One Portable Kit can operate any number of breakers, in tandem with breaker-specific Safe-T-Rack equipment.

*Additional tool adapters and/or equipment may be necessary. M18 and M28 equipment are not interchangeable, and will not cross-function. Questions or concerns? Contact our Sales Team today!

What does the sticker on my Smart Drive Bracket and Cubicle mean?

Each Safe-T-Rack© application is released to the customer with a corresponding “color code.” This name sticker (titled after a color or theme) not only specifies parts among our 300+ applications, but also assures that operators in the field can identify and confirm that they are utilizing the correct remote racking device for each breaker.

Tool code “colors” are specific to each application and can have names as simple as “Red” or as unique as “Lizard.” Browse our application library to learn more – or talk to our sales team to learn which color code will work for your device!

Contact our team to learn which Safe-T-Rack application operates your switchgear!

A Look at the Industry's Leading Motor Drive Unit

The Safe-T-Rack©

Motor Drive Unit:

Designed with power and portability in mind.

Powered by a rechargeable Milwaukee battery, this Motor Drive Unit (MDU) is equipped with a brushless motor and a tightly integrated gear reduction system. Motor Drive Units are available in M18 and M28 styles, operating with the corresponding Milwaukee battery and tailored to specific uses and capabilities, depending on application.

» Lightest MDU on the market, with more power!

A remote racking motor that’s easy for your crew to move and use, weighing around 9 pounds!

» Longer Running Time

Maximizing power and battery life for effective and safe remote racking

» Durable

Designed for years of use with a rugged weather-protected carrying case.

» Variable Torque and Force Feedback Technology

Auto-returns to slow torque and speed at the start and stop of the racking screw prevents equipment damage.

Our Custom Designed Smart Drive Brackets

» Portable and Convenient

Lightweight and streamlined, the Smart Drive Bracket is designed with portability in mind, with easy transfer from one cubicle to the next.

» Inbuilt Smart Card

Each Smart Drive Bracket contains a smart card programmed with software specific to the application

» Designed to be Durable

Smart Drive Brackets are engineered to last and built for heavy use in industrial environments. Brackets are Zinc-plated and built in-house in our Tucson, Arizona facility using only the best materials.

» No-Mod Options

Many applications are available in No-Mod designs, requiring no permanent alterations to equipment. Talk to our sales team today to learn if one of these designs is available for your equipment!

The Safe-T-Rack© Smart Drive Bracket

The Safe-T-Rack © Smart Drive Bracket is suspended from or secured to the cubicle of a breaker and supports the Motor Drive Unit (MDU) to complete the remote racking process. An SDB is designed specifically by application, but usually includes:

- Drive Rings with Locking pin – to support MDU during racking process

- Smart Card with pre-installed software specific to the breaker

- Communications Cable – will attach to MDU during racking process

- Keyhole Slots or Mounting Hardware to secure SDB to breaker

There are multiple styles of Smart Drive Brackets, specifically designed for each breaker or cubicle. Many SDBs are suspended from a cubicle using a pre-installed Cubicle Kit, which usually consists of shoulder bolts mounted to the cubicle. assuring correct and secure placement of the MDU during every racking sequence.

Lightweight Handheld Controller

Safety at the Tips of Your Fingers:

The Safe-T-Rack© Handheld Controller

This handheld controller communicates with the Smart Drive Bracket and Motor Drive Unit using communication cords and pre-programmed software, specific to each application and breaker.

» Ease of Operation

Intuitive, simplified buttons designed to be used with gloves or other equipment.

» Interprative and Interactive

Digital display relays turn counts and overall progress during racking process

» Designed for Fieldwork

Rubberized comfort grip and streamlined design for ease-of-use in the field.

» Updates in Real Time

Allows user to select desired action and displays expected location of breaker in the event of an error.

The Safe-T-Rack© Cubicle Kit

» Shoulder Nuts Directly Mounted to Cubicle

Accurate placement of Smart Drive Bracket with every use, shoulder nuts installed directly on cubicle support bracket via keyhole slots. Shoulder nut placement designated by template or Remote Solutions team member install.

» Supports Smart Drive Bracket and MDU

Cubicle kits supports Smart Drive Bracket and Motor Drive Unit during racking process.

» Strategic Design

Designed to require minimal changes to the breaker. Some designs use existing bolt holes and requiring no new holes to be drilled.

Additional Safe-T-Rack© Tools & Accessories

Many of the accessories below are included with various Safe-T-Rack© applications. Contact the Safe-T-Rack© Sales Team to learn more about the features and capabilities of a remote racking solution that aligns with your equipment and needs!

Battery

The SR-U family proudly uses Milwaukee M18 and M28 series cordless power tool batteries. These provide ample energy for hundreds of different racking applications in our lineup. Two batteries are provided in the portable kit for quick field changes.

Cables

Included with the Handheld Controller, the SR-U control cable features high-cycle duty mating connectors. The cable assembly is available in 50-foot segments that can be tethered with three cables for up to 150 feet of safe distance for the operator.

Additional Tools

Many Safe-T-Rack© products use additional tools to interact with the breaker and cubicle. Other applications are available with optional features and accessories, such as spanner bars or interlock assemblies. Learn more about these tools and accessories below.

Attaches to MDU to reach/interact with racking port.

Extends across cubicle to support SDB

Used between MDU and SDB and SDB and HHC to communicate turn counts, status of racking progress, and error messages.

Milwaukee Batteries and Charger – each kit includes two (2) batteries and a battery charger. We use the best batteries in the business, with replacements available from a variety of global retailers.

Integrates with interlock/racking port to successfully rack breaker.

Remote Solutions has engineered specific Interlock Assemblies for equipment that requires manipulation of interlock for successful operation. Contact our sales team for details!

Learn more about the industry’s most portable and capable remote racking system and request a product demo with our sales team today!