Switchgear Manufacturers Seek Effective, Reliable, and Portable Remote Racking Options for Equipment Builds

Safe-T-Rack systems are custom-built for specific lineups, offering manufacturers a safe, effective, customer-enticing remote racking option for new switchgear builds.

As with All Things, It Starts with Building Something:

Since the early days of the electrical grid, there have been lineups and switchgear built to manage the flow of electricity. Today, electrical equipment manufacturers seek to create safe, effective, and durable switchgear that manage electrical loads while also protecting operators and aligning with industry standards and requirements.

Safe-T-Rack remote racking systems have been evolving and improving since 2002, now leading the industry in portability, versatility, and scalability and protecting teams from arc flash risk across the world. Meanwhile, switchgear manufacturers are also evolving and growing, continually maintaining the balance between industry requirements for remote racking, efficiency and effective operation, and customer needs. Many manufacturers create their own remote racking options, distributed as standard additions to their equipment. Often, the driving force to include remote racking options in new switchgear builds is to satisfy industry regulations, with many manufacturers (understandably) focusing on equipment effectiveness and quality over remote racking.

This may be true in many cases, but not for a switchgear manufacturer on the East coast, who have consistently created robust and efficient remote racking systems for many of their products. As this company grew, their commitment to quality remained – with a consistent goal of maintaining this same high standard in future builds.

In stark opposition to the industry standard – manufacturer-built remote racking options with limited engineering and attention – this East coast manufacturer sought a more effective, safe, and customer-focused remote racking option. This search led them to Remote Solutions LLC, where they encountered Safe-T-Rack. An idea formed in their mind – and this was the start of a partnership that would build something completely new!

Safe-T-Rack remote racking systems have been evolving and improving since 2002, now leading the industry in portability, versatility, and scalability and protecting teams from arc flash risk across the world. Meanwhile, switchgear manufacturers are also evolving and growing, continually maintaining the balance between industry requirements for remote racking, efficiency and effective operation, and customer needs. Many manufacturers create their own remote racking options, distributed as standard additions to their equipment. Often, these remote racking options are included in equipment builds as almost an afterthought, with manufacturers (understandably) focusing on equipment operation effectiveness and quality.

Often, this means that manufacturer-built remote racking systems are included as almost an afterthought, with limited engineering and focus dedicated to this important safety element. This can result in sub-par inbuilt remote-racking. However, recently a switchgear manufacturer on the East coast looked at their options while designing new cubicles and encountered Safe-T-Rack. An idea formed in their mind – and this was the start of a partnership that would build something completely new!

Introducing a New Collaboration: Safe-T-Rack as Standard Remote Racking in new Switchgear Builds

This East coast switchgear manufacturer, JST Power Equipment, thought outside of the box. Instead of trying to build an in-house remote racking solution and strain resources, they turned to Remote Solutions LLC. The manufacturer had an important goal in mind: customer experience. In creating and selling their cubicles, the company wanted to ensure that customers would be able to safely and consistently operate and use the equipment without unnecessary hassle, labor, or risk.

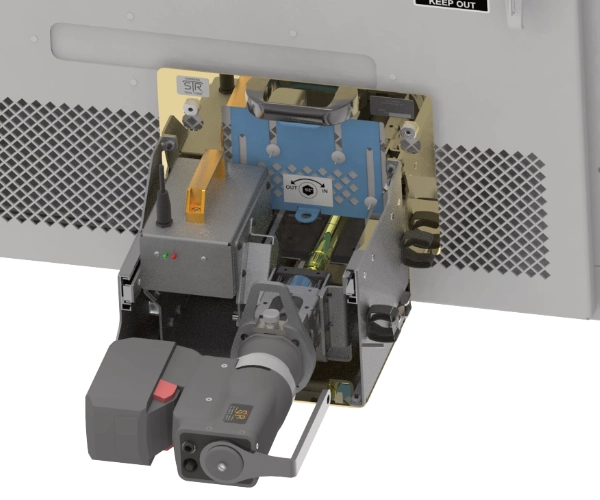

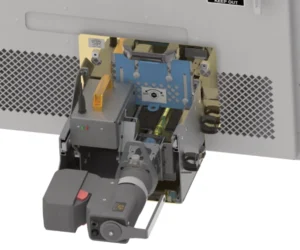

Enter: Safe-T-Rack. This portable and versatile remote racking system is custom-designed depending on equipment setup and end-user needs, and when the engineers at Remote Solutions LLC were tasked with a new challenge – creating and launching a brand new remote racking bracket that racked this specific switchgear – the team leapt at the opportunity.

Within a few short weeks. the Engineering Team at Remote Solutions LLC developed a brand new smart drive bracket, built and programmed to effectively operate both the racking mechanism and automate the interlock mechanism on these new cubicles. The design was tested and demonstrated to the customer soon after.

Learn more about CARRERA!

This remote racking system allows your team to operate 15kV, 50kA, 1200-3000A J3Mag® Breakers from distances of up to 150 feet, protecting them from arc flash risk. This unique system was specifically designed for JST equipment, automating both the racking and interlock features of the breaker remotely.

Final Additions and Polish

As with many new endeavors, the first test run was not the end-all answer. After some product testing on-site at the manufacturer’s facility, it was discovered that the original application – designed on a test breaker – required slight alterations to successfully operate an in-service cubicle and breaker.

The Safe-T-Rack team was not daunted by this challenge. They quickly created a gearbox that would allow the system additional torque to complete required tasks. This update was completed and shipped out within days, and all subsequent builds integrated this update – assuring that this remote racking system remained a convenient and effective safety measure in all new switchgear builds and sales for these breakers.

Safe-T-Rack Integration: a Recipe for Success for Suppliers and End-Users!

With the custom design and effective implementation of Safe-T-Rack remote racking systems into their builds, this facility was able to offer customers an attractive remote racking system without challenging customer experience or compromising safety. Learn more about JST Power Equipment here!

For more information about Safe-T-Rack remote racking systems and to protect your team from arc flash risk, contact our team today!

Find a Remote Racking Solution for your Equipment! Search breaker, manufacturer, or amperage here!

The Latest News from Remote Solutions:

Switchgear Manufacturer turns to Safe-T-Rack for Custom Remote Racking Solution

Switchgear Manufacturers Seek Effective, Reliable, and Portable Remote Racking Options for Equipment Builds Safe-T-Rack systems are custom-built for specific lineups, offering manufacturers a safe, effective, customer-enticing remote racking option for new switchgear builds. As with All Things, It Starts with Building Something: Since the early days of the electrical grid, there have been lineups and

Power Generation Facility Implements Safe-T-Rack After OSHA Reportable Arc Flash Incident

The Time to Implement Safe-T-Rack is NOW Before an Arc Flash Incident Occurs An OSHA Reportable Lost Time Incident Occurs In 2020, on the East Coast of the United States, a power generation facility experienced an unfortunate arc flash event which severely injured an operator and significantly damaged equipment. A General Electric Limitamp contactor arced

Safe-T-Rack Adapts Remote Racking System to Operate Overhead Switches with new Product: ULTRAVIOLET

ULTRAVIOLET: Remote Overhead Switch Operation using the Safe-T-Rack Remote Racking System The Customer Request: Remote Overhead Switch Operation For almost 20 years, Remote Solutions LLC has developed and refined innovative, portable remote racking systems with the goal of making arc flash safety convenient and effective for facilities all over the world. Safe-T-Rack remote racking systems