NEW YEAR: RENEWED MISSION

SAFE-T-RACK REMOTE RACKING SYSTEMS CONTINUE TO SAVE LIVES AND PROTECT SWITCHGEAR IN 2025.

Remote racking systems for electrical circuit breakers not only save lives, but with the right system – such as a Remote Racking System by Safe-T-Rack – this tool can help extend the longevity of equipment in addition to protecting the lives of your team.

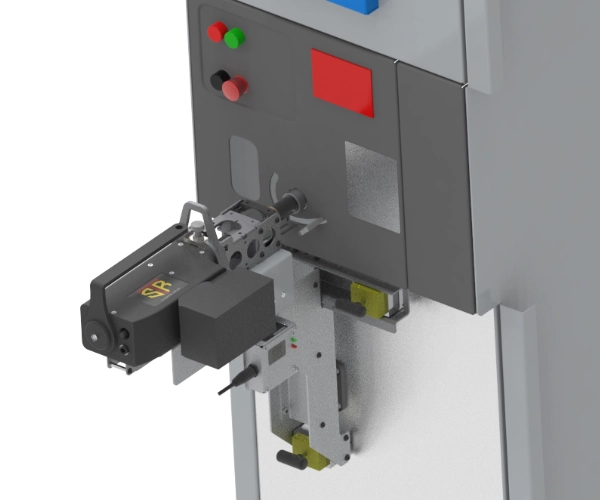

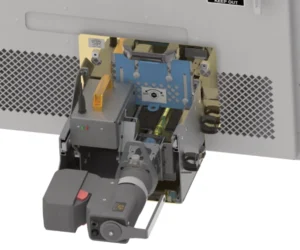

For years, Safe-T-Rack has proven itself a trusted asset in the battle against Arc Flash injuries. With intuitive and advanced equipment tailored to customer needs, Safe-T-Rack offers a portable, reliable, and scalable remote racking system for your team. The added benefit to Safe-T-Rack’s custom designs? Each Safe-T-Rack Smart Drive Bracket is programmed with equipment-specific software parameters, tailoring the tool’s actions to the relevant equipment – including turn counts and torque.

In contrast to alternate remote racking options, Safe-T-Rack not only reduces arc flash injury risk but also protects equipment from potential damage due to human error.

Every Safe-T-Rack remote racking system is developed for a specific breaker, which means the software is also tailored to the unique requirements of that equipment. How does software contribute to overall equipment longevity? Because Safe-T-Rack’s pre-programmed turn counts and torque settings ensure that the remote racking process is completed without risk of over or under-torquing the breaker.

What happens when you over-torque a breaker?

Over-torquing a breaker may lead to increased pressure on the equipment, potentially causing damage to internal controls and thereby increasing the risk of arc flash incidents. Additionally, over-torquing can cause damage to equipment in the form of broken bolts or fasteners or other structural issues. When racking a breaker without utilizing specific tools, it is easy to unintentionally over-torque, especially when attempting to confirm that the racking process is completed.

By comparison, under-torquing a breaker may cause the equipment to be less firmly sealed against the elements, allowing debris and other potentially damaging elements to enter the breaker. These irritants can cause undue wear and tear on internal equipment, and can interfere with the racking process in future.

Both over and under-torquing a breaker can contribute to potential equipment damage and increase risk of an arc flash incident.

How does Safe-T-Rack Remote Racking System protect equipment from potential damage?

With each breaker-specific Safe-T-Rack remote racking system, you can rest assured that the team at Remote Solutions has researched the equipment and implemented software that aligns with the equipment’s setup and process.

Remote racking systems by Safe-T-Rack are always programmed with specific turn counts and travel patterns, but what truly sets the system apart is the intuitive and automated error detection and recovery protocol. If the system senses increased pressure or any unexpected issue during the racking process, Safe-T-Rack systems are intelligent enough to suspend travel and alert the user of a potential issue – as opposed to powering through an equipment failure and causing even more damage to equipment or inducing an arc flash incident.

Safe-T-Rack in Action – Responsive Programming Saving Lives and Equipment

On multiple occasions, the Safe-T-Rack remote racking system has helped both to prevent Arc Flash incidents and to protect equipment. For example, the Safe-T-Rack team recently responded to a customer concern involving a remote racking system that did not complete the remote racking process.

The customer contacted Remote Solutions to report this unexpected operational delay and informed the team that their Remote Racking system presented an error and consistently stopped the racking process before completely racking the breaker. The system had successfully racked a breaker within the last 24 hours and the team was anxious to continue the work they had started. The customer requested that the remote racking system be altered to include more torque and force, with the goal of pushing through the error code.

The Safe-T-Rack team quickly worked to assess and troubleshoot the situation. Once the team had confirmed that everything in the remote racking system was operating normally and that there was no issue with the racking system’s hardware or software, they assessed the customer’s request that the power on the system be turned up to drive through whatever was impeding the system from completing the racking process.

Since each Smart Drive Bracket is specifically programmed to the breaker in question, the team was reluctant to make this change and increase power without first assessing the breaker for potential damage or issues. This concern was relayed to the customer, who rolled out the breaker and checked the mechanism to make sure everything was in order.

Upon closer inspection, the customer discovered that the shutter in the breaker was not opening, and therefore the breaker was not working properly. This failure had been detected by the Safe-T-Rack system, causing the system to repeatedly stop the racking process and report the error.

Thanks to the intuitive programming of the Safe-T-Rack remote racking system, a situation was prevented that could have been extremely dangerous for someone manually over-torquing a broken breaker or increasing torque on a racking system to manipulate a malfunctioning breaker.

The team at Remote Solutions works to prevent arc flash injury and reduce risk to equipment and switchgear, continually innovating and developing new products and features to further these goals. Our remote racking systems save lives and protect equipment in facilities across the country.

Want to learn more about protecting your team and your equipment with one custom-designed, portable, and intuitive remote racking system? Contact our sales team today!

*Patent Pending. For more information, please visit: safe-t-rack.com/Patent/

Find a Remote Racking Solution for your Equipment! Search breaker, manufacturer, or amperage here!

The Latest News from Remote Solutions:

Switchgear Manufacturer turns to Safe-T-Rack for Custom Remote Racking Solution

Switchgear Manufacturers Seek Effective, Reliable, and Portable Remote Racking Options for Equipment Builds Safe-T-Rack systems are custom-built for specific lineups, offering manufacturers a safe, effective, customer-enticing remote racking option for new switchgear builds. As with All Things, It Starts with Building Something: Since the early days of the electrical grid, there have been lineups and

Power Generation Facility Implements Safe-T-Rack After OSHA Reportable Arc Flash Incident

The Time to Implement Safe-T-Rack is NOW Before an Arc Flash Incident Occurs An OSHA Reportable Lost Time Incident Occurs In 2020, on the East Coast of the United States, a power generation facility experienced an unfortunate arc flash event which severely injured an operator and significantly damaged equipment. A General Electric Limitamp contactor arced

Safe-T-Rack Adapts Remote Racking System to Operate Overhead Switches with new Product: ULTRAVIOLET

ULTRAVIOLET: Remote Overhead Switch Operation using the Safe-T-Rack Remote Racking System The Customer Request: Remote Overhead Switch Operation For almost 20 years, Remote Solutions LLC has developed and refined innovative, portable remote racking systems with the goal of making arc flash safety convenient and effective for facilities all over the world. Safe-T-Rack remote racking systems