Remote Racking for RMUs - by Safe-T-Rack©

Safe-T-Rack is the most capable and portable remote racking system on the market, reducing arc flash incidents in countless facilities across the country. Recently the company had an opportunity to expand its applications to new use cases – and, more excitingly, new continents!

Historically, Safe-T-Rack excels in remote circuit breaker racking for medium and high-voltage environments, but now the concept has expanded for use in a variety of additional environments. In this case, Remote Solutions channeled years of industry expertise to recalibrate their designs for the operation of Ring Main Units (RMUs) at a wind farm in Australia.

The Safe-T-Rack remote racking system has garnered international recognition in recent years, the portable and lightweight product offered by Remote Solutions being ideal for sprawling outdoor environments. This captured the interest of the Australian wind farm, which routinely generates, manages, and transmits enormous amounts of electrical power and uses a variety of switchgear to effectively operate their business. Among the switchgear are an assortment of Ring Main Units (RMUs), for which the facility sought an effective, portable, and reliable remote racking system to keep their employees safe.

The wind farm considered their options, and ultimately elected to contact Remote Solutions LLC about the Safe-T-Rack product, requesting a custom-designed, portable, and reliable remote racking system for all their Ring Main Units operating DC breakers.

Once contact was established, the engineers and designers at Remote Solutions LLC got to work. Even from the other side of the world in Tucson, Arizona, the Remote Solutions team made quick work of a prototype design, flexing their knowledge of electrical circuit breakers and adaptable bracket configurations to align with the wind farm’s unique needs in Australia. Even without physically interacting with the environment, the team of engineers quickly devised a remote racking strategy for the wind farm’s RMUs. This design and delivery are notable, as it demonstrates the Remote Solutions team’s ability to communicate, design, create, install, and train a facility on a custom-designed product without setting foot in the facility, or even on the same continent as the facility.

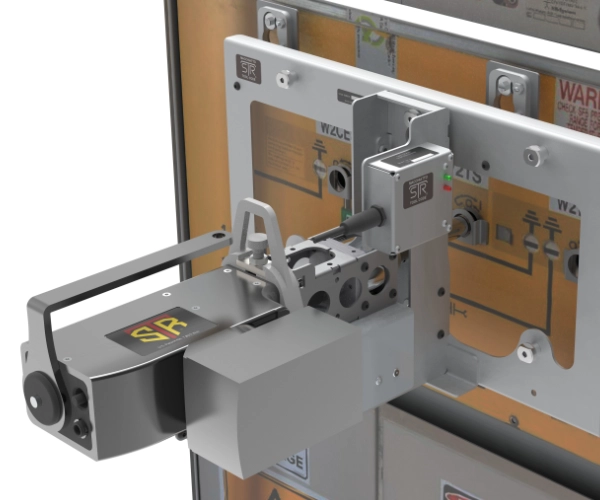

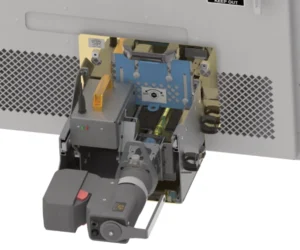

Using an M28 Motor Drive unit, a custom-designed Spanner Bar and Smart Drive Bracket, and a a specially designed tool chuck to interact with the racking port, the system (dubbed MACCHIATO) was tailored for use in RMUs, specifically created for the equipment housed at the Australia wind farm. The spanner bar mounts onto the RMU with pre-installed shoulder nuts (part of the Safe-T-Rack Cubicle Kit) and proffers an assortment of shoulder nut locations to allow multiple mounting options for the Smart Drive Bracket. This allows the equipment operator to determine and select which switch to operate on the RMU.

Once the spanner bar and Smart Drive bracket are in place, the system operates much like many other Safe-T-Rack remote racking applications. The Smart Drive Bracket communicates with the M28 motor drive unit and Handheld Controller, initiating the racking sequence with guidance from the operator and relaying current sequence status. The operator controls and monitors the process through the Handheld Controller, which functions up to 150 feet from the RMU – safely out of range of any potential arc flash activity.

Through this combination of custom design, industry expertise, and client requirements, MACCHIATO allows this facility to remotely rack their RMUs safely and effectively, protecting their team and reducing the man hours required to operate the equipment by hand. All the design work was completed in the Remote Solutions Tucson, Arizona facility, while the final product is currently in use thousands of miles away in Australia. This entirely remote approach demonstrates not only the Safe-T-Rack team’s ability to brainstorm, research, engineer, and implement remote racking solutions for new equipment, but also their ability to do all of this – testing and troubleshooting included – from half a world away.

MACCHIATO continues to operate as a valuable tool for the remote operation of RMU systems. For more information or to request a custom design for your facility or equipment, contact the Remote Solutions sales team today.

Find a Remote Racking Solution for your Equipment! Search breaker, manufacturer, or amperage here!

The Latest News from Remote Solutions:

Switchgear Manufacturer turns to Safe-T-Rack for Custom Remote Racking Solution

Switchgear Manufacturers Seek Effective, Reliable, and Portable Remote Racking Options for Equipment Builds Safe-T-Rack systems are custom-built for specific lineups, offering manufacturers a safe, effective, customer-enticing remote racking option for new switchgear builds. As with All Things, It Starts with Building Something: Since the early days of the electrical grid, there have been lineups and

Power Generation Facility Implements Safe-T-Rack After OSHA Reportable Arc Flash Incident

The Time to Implement Safe-T-Rack is NOW Before an Arc Flash Incident Occurs An OSHA Reportable Lost Time Incident Occurs In 2020, on the East Coast of the United States, a power generation facility experienced an unfortunate arc flash event which severely injured an operator and significantly damaged equipment. A General Electric Limitamp contactor arced

Safe-T-Rack Adapts Remote Racking System to Operate Overhead Switches with new Product: ULTRAVIOLET

ULTRAVIOLET: Remote Overhead Switch Operation using the Safe-T-Rack Remote Racking System The Customer Request: Remote Overhead Switch Operation For almost 20 years, Remote Solutions LLC has developed and refined innovative, portable remote racking systems with the goal of making arc flash safety convenient and effective for facilities all over the world. Safe-T-Rack remote racking systems