The Time to Implement Safe-T-Rack is NOW

Before an Arc Flash Incident Occurs

An OSHA Reportable Lost Time Incident Occurs

In 2020, on the East Coast of the United States, a power generation facility experienced an unfortunate arc flash event which severely injured an operator and significantly damaged equipment.

A General Electric Limitamp contactor arced during operation (open to closed) and caused an arc flash that impacted and injured the operator. Without Safe-T-Rack remote racking, in order to operate the contactor and operator must stand within arm’s reach of the contactor handle and manually shift the contactor between the open and closed positions. This put the team at significant risk of injury in the event of an arc flash event.

Implementing Safe-T-Rack

Soon after the event, the power generation facility contacted Safe-T-Rack, with the goal of protecting their operators by implementing a reliable, portable, and versatile remote racking system. The engineers and designers at Safe-T-Rack quickly got to work designing an application that would operate these large contactors remotely, putting distance between operators and equipment that incurs arc flash risk.

The facility had one additional request: they did not want to alter their existing equipment – they wanted a remote racking system that would attach to a contactor and operate without additional hardware installation. This added an additional challenge for the Safe-T-Rack team, as the hardware required for the design and operation of the contactor was heavy and considerably bulky, but the Safe-T-Rack team soon devised a solution.

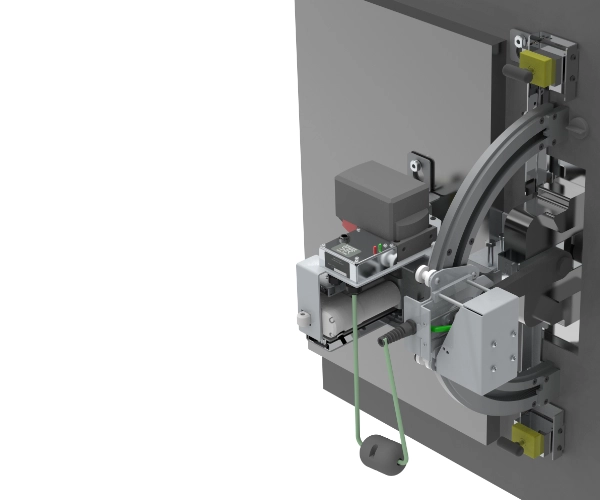

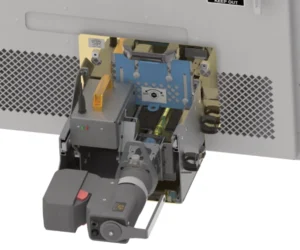

The Aventurine remote racking system was introduced to the power generation facility a few weeks later. This innovative remote operating system included a half-moon arced support to guide the operation of the lever, and – like all other Safe-T-Rack systems – includes a custom-programmed smart card, which specifically operates GE Limitamp Contactors and controls the movement of the bracket, including hard stops and path of travel, with the goal of attaining a successful remote racking operation with every use.

Unlike other Safe-T-Rack systems, this remote open/close device does not use the patented Safe-T-Rack M18 Motor Drive unit, instead relying on M18 batteries to operate the system, the motor and operation elements of which are all built into the Smart Drive Bracket.

The most innovative element of this system, however, was the no-mod setup. The Safe-T-Rack engineers were able to create, test, and deploy a system that operates these contactors, supports a significant amount of hardware, and attaches to the contactor using three powerful locking magnets. Want to learn more about how it works? Check out the Aventurine page!

Learn more about Aventurine!

This remote racking system allows your team to operate GE Limtamp contactors from distances of up to 150 feet, protecting them from arc flash risk. This unique system was specifically designed for GE Limitamp equipment, and is a no-mod design - meaning it does not require alterations to cubicles or equipment, instead using secure locking magnets during operation.

Safe-T-Rack Saves Lives

The power generation facility quickly implemented Safe-T-Rack remote racking systems into their processes. The teams on-site using the new system were accepting of the change, noting the portability and capability of the bracket. Almost immediately the facility began and securely operating equipment from distances of up to 150 feet. At the time of this article, there has not been another arc flash incident causing injury or lost-time at this facility since the implementation of Safe-T-Rack.

For more information about Safe-T-Rack remote racking systems and to protect your team from arc flash risk, contact our team today!

Find a Remote Racking Solution for your Equipment! Search breaker, manufacturer, or amperage here!

The Latest News from Remote Solutions:

Switchgear Manufacturer turns to Safe-T-Rack for Custom Remote Racking Solution

Switchgear Manufacturers Seek Effective, Reliable, and Portable Remote Racking Options for Equipment Builds Safe-T-Rack systems are custom-built for specific lineups, offering manufacturers a safe, effective, customer-enticing remote racking option for new switchgear builds. As with All Things, It Starts with Building Something: Since the early days of the electrical grid, there have been lineups and

Power Generation Facility Implements Safe-T-Rack After OSHA Reportable Arc Flash Incident

The Time to Implement Safe-T-Rack is NOW Before an Arc Flash Incident Occurs An OSHA Reportable Lost Time Incident Occurs In 2020, on the East Coast of the United States, a power generation facility experienced an unfortunate arc flash event which severely injured an operator and significantly damaged equipment. A General Electric Limitamp contactor arced

Safe-T-Rack Adapts Remote Racking System to Operate Overhead Switches with new Product: ULTRAVIOLET

ULTRAVIOLET: Remote Overhead Switch Operation using the Safe-T-Rack Remote Racking System The Customer Request: Remote Overhead Switch Operation For almost 20 years, Remote Solutions LLC has developed and refined innovative, portable remote racking systems with the goal of making arc flash safety convenient and effective for facilities all over the world. Safe-T-Rack remote racking systems