Recently, an electrical generation facility in New Mexico faced a complex challenge: the facility managed a large fleet of Westinghouse Ampgard contactors which controlled machines integral to the business – and while maintenance and operation of a contactor is routine, the actual practice of operating these contactors quickly became an issue.

With employee safety at the forefront of their efforts, the facility ordered and carefully reviewed the results of an arc flash study for their location. The study revealed that available incident energy for all of the contactors was well above the protective capabilities of available Personal Protective Equipment (PPE) – meaning the contactors could not be operated safely by hand while energized.

When prioritizing between employee safety and uninterrupted power generation, employee safety obviously came first. As a result, whenever the contactors were maintained or operated, the entire lineup of equipment was deenergized – dozens of contactors standing idle. This process was highly time consuming and reduced operation uptime, hindering business success.

The facility reached out to Remote Solutions, seeking a remote racking option that would allow their technicians to safely operate these contactors from a distance, without needing to power down the entire lineup.

With that goal in mind, the business specified two additional requests. They relayed to the Remote Solutions team their desire for a portable remote racking system, giving their technicians the ability to move conveniently between contactors as needed. Additionally, the facility did not want to make any major alterations to their cubicles and equipment. In response, Remote Solutions communicated these requests to their team of engineers and immediately began developing a solution.

Designed to the exact specifications of the facility’s cubicles, AMARETTO was intentionally and strategically engineered to require no permanent alterations to the facility’s equipment.

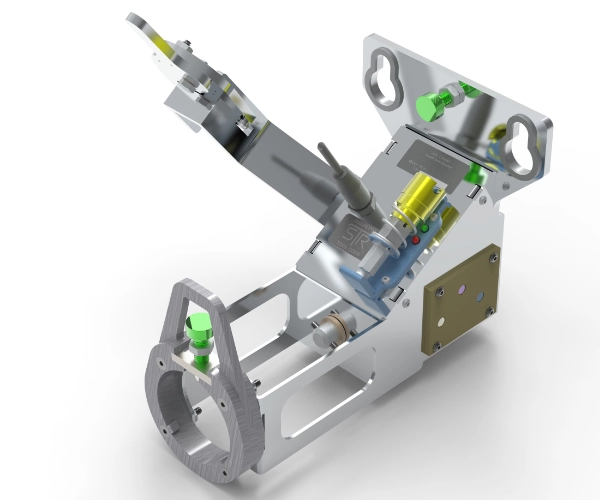

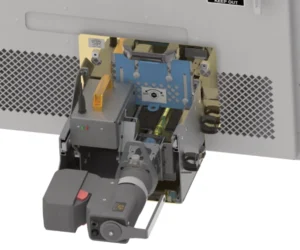

From these requirements, AMARETTO was created – a remote racking system that can operate these contactors from a safe distance. Designed to the exact specifications of the facility’s cubicles, AMARETTO was intentionally and strategically engineered to require no permanent alterations to the facility’s equipment. The application includes a Cubicle Kit, which attaches to the breaker using existing bolt holes and sits flush against the cubicle face. The Smart Drive Bracket, also specifically developed for Westinghouse Ampguard contactors, suspends from this cubicle kit and attaches to the handle of the contactor.

Once suspended from the cubicle, this Smart Drive Bracket supports a Motorized Drive Unit, which interfaces with the bracket’s hardware and pre-programmed software to operate the contactor. This process is controlled by a corded handheld controller, functional at distances of up to 150 feet -so that the contactor can be remotely operated by an employee from a safe distance – without powering down the surrounding cubicles.

In developing this industry-first remote racking system, Remote Solutions delivered a solution tailored both to the facility’s equipment and business needs, allowing this power generation facility to remotely operate each of their Westinghouse Ampguard contactors without deenergizing the equipment or risking employee safety. This remote racking system holds value for many similar businesses, and AMARETTO is now used in dozens of facilities across the country.

Remote Solutions continues to design, build, and implement remote racking solutions all over the world. If the company does not have an existing application that will meet a business’ needs, a new product can be designed and built. Portable, reliable, and effective in maintaining employee safety, Remote Solutions develops remote racking systems engineered to succeed.

Find a Remote Racking Solution for your Equipment! Search breaker, manufacturer, or amperage here!

The Latest News from Remote Solutions:

Switchgear Manufacturer turns to Safe-T-Rack for Custom Remote Racking Solution

Switchgear Manufacturers Seek Effective, Reliable, and Portable Remote Racking Options for Equipment Builds Safe-T-Rack systems are custom-built for specific lineups, offering manufacturers a safe, effective, customer-enticing remote racking option for new switchgear builds. As with All Things, It Starts with Building Something: Since the early days of the electrical grid, there have been lineups and

Power Generation Facility Implements Safe-T-Rack After OSHA Reportable Arc Flash Incident

The Time to Implement Safe-T-Rack is NOW Before an Arc Flash Incident Occurs An OSHA Reportable Lost Time Incident Occurs In 2020, on the East Coast of the United States, a power generation facility experienced an unfortunate arc flash event which severely injured an operator and significantly damaged equipment. A General Electric Limitamp contactor arced

Safe-T-Rack Adapts Remote Racking System to Operate Overhead Switches with new Product: ULTRAVIOLET

ULTRAVIOLET: Remote Overhead Switch Operation using the Safe-T-Rack Remote Racking System The Customer Request: Remote Overhead Switch Operation For almost 20 years, Remote Solutions LLC has developed and refined innovative, portable remote racking systems with the goal of making arc flash safety convenient and effective for facilities all over the world. Safe-T-Rack remote racking systems